- The German Autopreneur

- Posts

- Why Legacy Automakers Take 2x Longer to Build Software Than Tesla

Why Legacy Automakers Take 2x Longer to Build Software Than Tesla

Welcome to Issue #77 of The German Autopreneur!

A new McKinsey study shows:

Traditional car companies need 40-50 months to build new vehicle software.

Tesla and BYD build an entire car (including software) in 24-30 months. Some Chinese players do that in just 18 months.

This speed difference is becoming the deciding factor.

And legacy automakers recognize this. They're spending big on software. Volkswagen alone put over €12 billion into CARIAD.

But still, the software gap keeps growing.

Today we'll examine why established automakers are falling behind on software. And what they can do to catch up.

AI generated image

Why Software Matters in Cars

First: When we talk about car software, we don't just mean the screen.

Software now runs almost everything in your car:

Engine and brakes

Battery management

Safety systems and driving aids

App updates and new features

Many car launches got delayed because of software problems:

Audi Q6 e-tron (16 months late)

Porsche Macan (12 months late)

Volvo EX90 (6 months late)

Ford Explorer EV (6 months late)

This means: Software now determines vehicle development schedules. Fall behind here, and you lose.

The Old Development Method Is the Problem

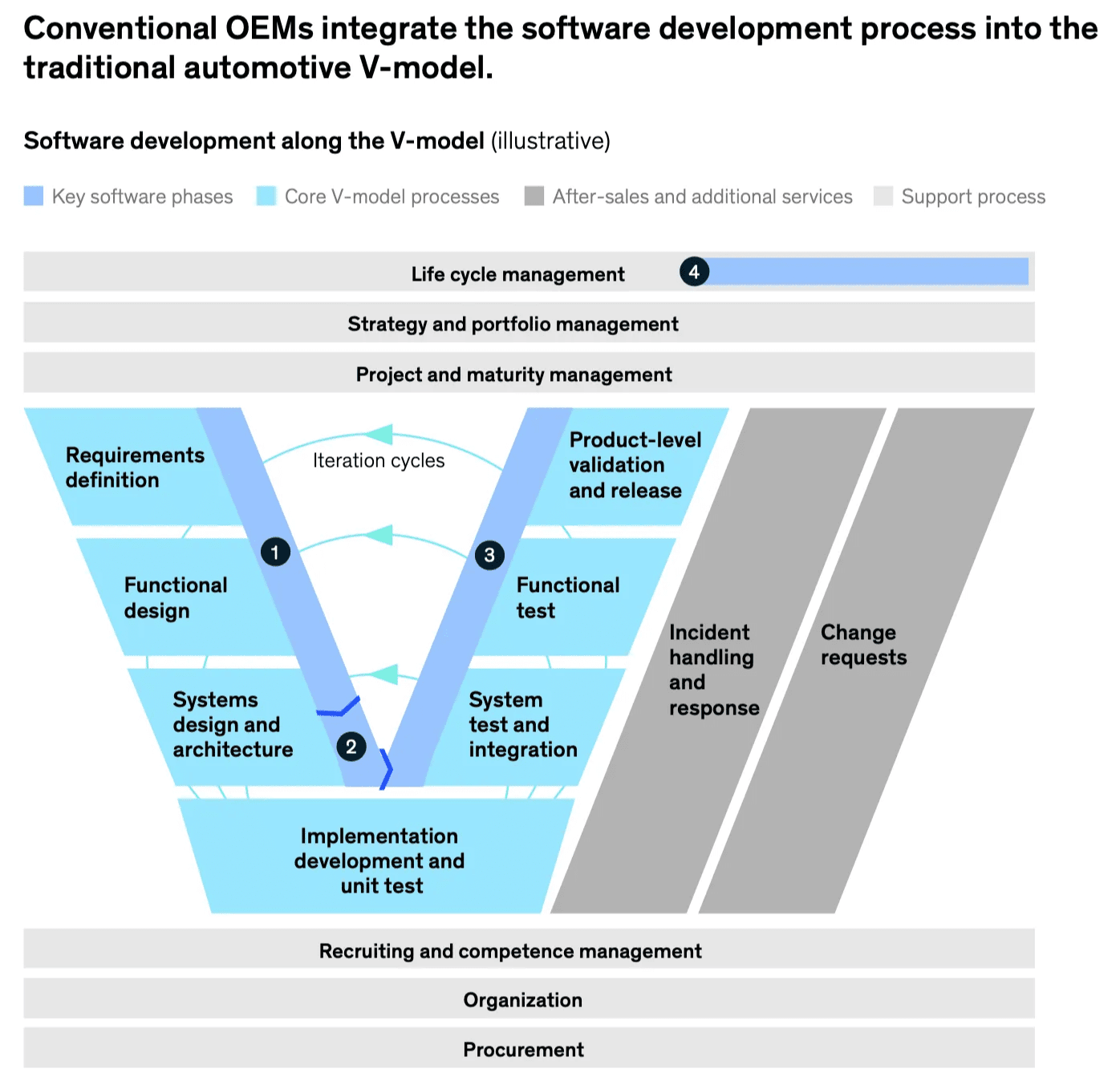

Traditional automakers develop vehicles using the V-model:

The V-model used in the automotive industry (Source: McKinsey)

This method is from the 1970s. It was made for building hardware. But it has two big problems for software:

Teams work in silos. For example, those defining requirements aren't involved in testing.

Waterfall approach. Each phase must be completed before the next begins. Feedback usually comes too late.

Here's a real example: Purchasing and development often communicate poorly. Procurement negotiates with suppliers without fully understanding technical requirements.

Too Many Car Models Slow Everything Down

Here's a problem most people miss: Traditional carmakers make 150x more car variants than new competitors.

What does this mean? A traditional carmaker has to:

Support dozens of different car models

Build combustion engines, electric motors, and hybrids at the same time

Keep multiple software systems running

Meet different rules in different countries

Result: Every software change has to work with hundreds of car variants. This costs tons of money. And makes everything super slow.

4 Big Problems McKinsey Found

1) Messy Tool Stack

Tech companies use modern, connected tools. Traditional carmakers use a patchwork of different systems. One tool for planning. Another for testing. A third for tracking bugs. And a lot of Excel sheets. Every transfer slows things down.

2) Bad Project Management

Different teams often have different plans for the same feature. Nobody knows what's really happening.

3) Using Hardware Methods for Software

Traditional processes were designed for hardware. They don't fit the iterative, fast nature of software development. Automakers tried to squeeze software into existing hardware processes instead of establishing new processes.

4) Rules Keep Changing

Quality criteria often change during development. What was initially accepted fails later in testing. This delays production starts by months.

The Talent Gap

Here's a hidden problem: The shortage of software talent. German car companies created 85% more IT jobs since 2013. But it's still not enough.

Car companies now compete with tech companies for the same people.

And first thing these tech companies do? Xiaomi opened an office in Munich and immediately hired 5 managers away from BMW.

But the problem is deeper. German corporate structures aren't built for software talent:

Union pay rules, like those from IG Metall, limit most salaries to €85,000-95,000. You need to manage people to earn more. In contrast: Google Germany pays an average of €165,000

There exists no real technical career path. You had to become a manager to advance. BMW only started a technical expert track in 2018

Remote work gets blocked. Software people want flexibility

Result: Hardware engineers who don't understand software end up managing software teams. They can handle suppliers. But they don't know software.

What New Carmakers Do Right

Tesla fixes 99% of its recalls via over-the-air updates. This isn't coincidence, but the result of a different development approach.

New carmakers:

Put software first, hardware second

Mix hardware and software teams together

Work in short 1-2 week cycles

Reuse the same code across different cars

The key point: They think of themselves as software companies that happen to make cars. Not car companies that use some software.

5 Ways to Build Software Faster

I found 5 ways traditional carmakers can speed up their software:

1) Put Software First

Software has to be the starting point. Not something you add later. This means software experts need to be in charge. Software leadership should be the norm, not the rare exception.

2) Change How You Develop

You can test software using virtual simulations. Get feedback fast instead of waiting months to build physical prototypes.

3) Fix Your People Problem

Create new career paths for technical experts. Pay them what they're worth. And let them work remotely.

4) Make Fewer Car Models & Variants

Every extra variant costs development time. Build one software system for all of your cars.

5) Work Together

McKinsey suggests carmakers should build software together. Like how Airbus was created. In Germany S-CORE is a first step, as I reported two weeks ago.

My Take

Traditional automakers' biggest problems aren't technical. It’s about how companies are organized and their company culture.

The good news? This can be fixed. The bad news? Everything needs to change.

Three things matter most:

Software delays cost millions. Every month a car is late costs serious money.

The old development method is from the hardware era. It needs to be rebuilt for software.

Our rigid structures are blocking change. The way we hire and pay people was built for the last century. We're competing for software talent with one hand tied behind our back.

McKinsey confirms this: Software got squeezed into old processes like the V-model, instead of creating new ones. We're trying to build software like we used to build car engines.

Small fixes won't work. Traditional carmakers need complete transformation. From hardware to software-first companies.

That's all for today.

What did you think of today's email? |

Feel free to reply to this email with your thoughts.

Until next week,

— Philipp

PS: If you find value in this newsletter, please share it with someone who might benefit. Your support helps me continue my independent work for the automotive industry.