- The German Autopreneur

- Posts

- Germany Needs Robots. But Will Fight Them

Germany Needs Robots. But Will Fight Them

Welcome to Issue #100 of The German Autopreneur.

The biggest race in automotive? It's not about range anymore. Not about charging speed. It's about robots.

CES wrapped up in Las Vegas last week. Hyundai made a stunning announcement: They'll produce 30,000 humanoid robots per year starting in 2028.

They're serious.

And Hyundai isn't alone. Tesla builds Optimus. BMW started with Figure two years ago. Mercedes pilots Apollo. BYD plans 20,000 humanoids by end of 2026.

The race is on.

A pattern emerges: Automakers don't just build with robots anymore. They're now building robots themselves.

What's happening here? And what does it mean?

Why Automakers Suddenly Build Robots

A modern car is basically a robot on four wheels.

Same batteries. Same electric motors. Same sensors. Same AI chips. The supply chains overlap significantly.

If you can build cars, you can build robots.

Elon Musk says: "Optimus will be worth more than our car business."

Hyundai's Chairman: "Robotics will be 20% of our business by 2030."

These aren't side projects. Robots are becoming automakers' next big bet.

The Brownfield Advantage

Here's where it gets interesting.

Our factories were built for humans. Stairs. Narrow corridors. Tools designed for hands.

Traditional industrial robots need brand-new, empty halls. Full factory rebuilds. That costs billions.

But humanoid robots are different. They fit directly into existing workflows.

Boston Dynamics' Atlas (Hyundai's robotics subsidiary) walks through the same door as you do. Picks up the same screwdriver. Climbs the same stairs.

Our world is built for humans. That's exactly why humanoids work.

This is the Brownfield Advantage: Automation without the need for factory reconstruction.

Hyundai's humanoid robot Atlas (Boston Dynamics)

The Brutal Math

The economic logic isn't new.

In 2015, Volkswagen's HR chief calculated: A robot costs only a fraction of a skilled worker. But back then, robots lacked flexibility.

Not anymore.

A German factory worker costs about €45 per hour. A humanoid robot: €12 to €15 per hour, and the price keeps falling.

The math works everywhere. High-wage countries have the strongest incentive. But even in lower-cost regions, the gap is closing.

What the Sceptics Say

Not everyone's convinced.

In early 2025, a Fraunhofer study concluded: Humanoid robots are a dead end. At least for now. Too slow. Too unreliable. Too unsafe.

They have a point. Many humanoids today only have 2 to 4 hours of battery life. Not exactly factory-ready.

But that's short-sighted. This isn't about what's possible today. It's about the future. And that future arrives faster than many think.

Two things accelerate development:

The demographic crisis. Nobody wants to do repetitive, physically demanding jobs anymore

AI advancement. Robots aren't programmed anymore. They're trained. What used to take years is now learned through demonstration. Within weeks.

And here's what sceptics miss.

If you wait until robots are "perfect"? You'll have a problem. You miss out on training data from your own factory. The real-world experience.

Tesla doesn't run Optimus because it's perfect. They run it so that it becomes perfect.

Because when one robot learns a task, all others can use that knowledge instantly. One learns, all can do it. That's the fundamental difference from humans.

Where We Stand Today

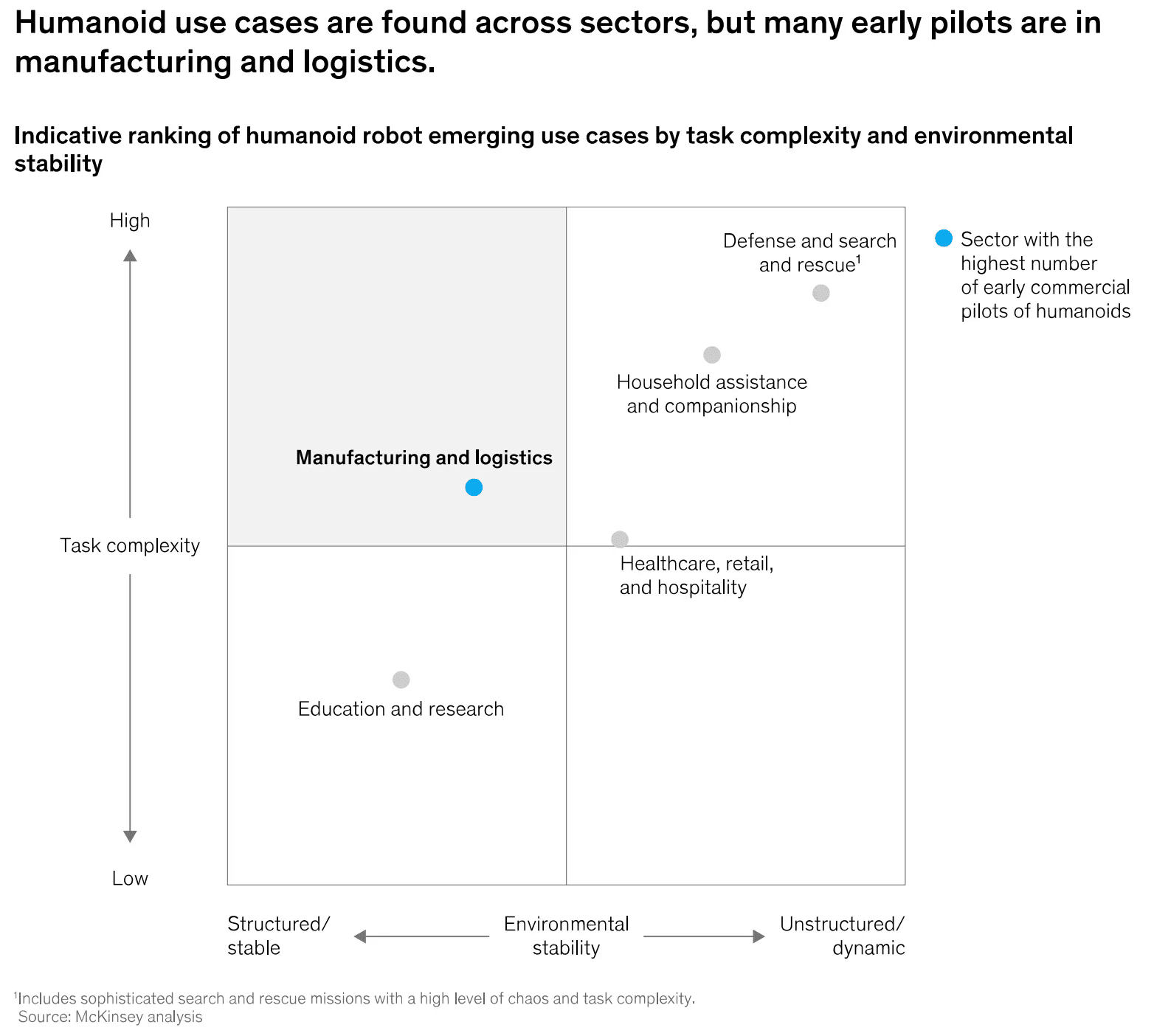

So where do things actually stand? A few companies are already testing humanoids in real factories.

BMW started a Figure pilot in Spartanburg in 2024. The robots place metal sheets into body panels. Over 30,000 BMW X3s have been built this way.

Tesla deploys hundreds of Optimus robots in its Gigafactories. They sort battery cells.

Humanoids start where environments are stable (McKinsey)

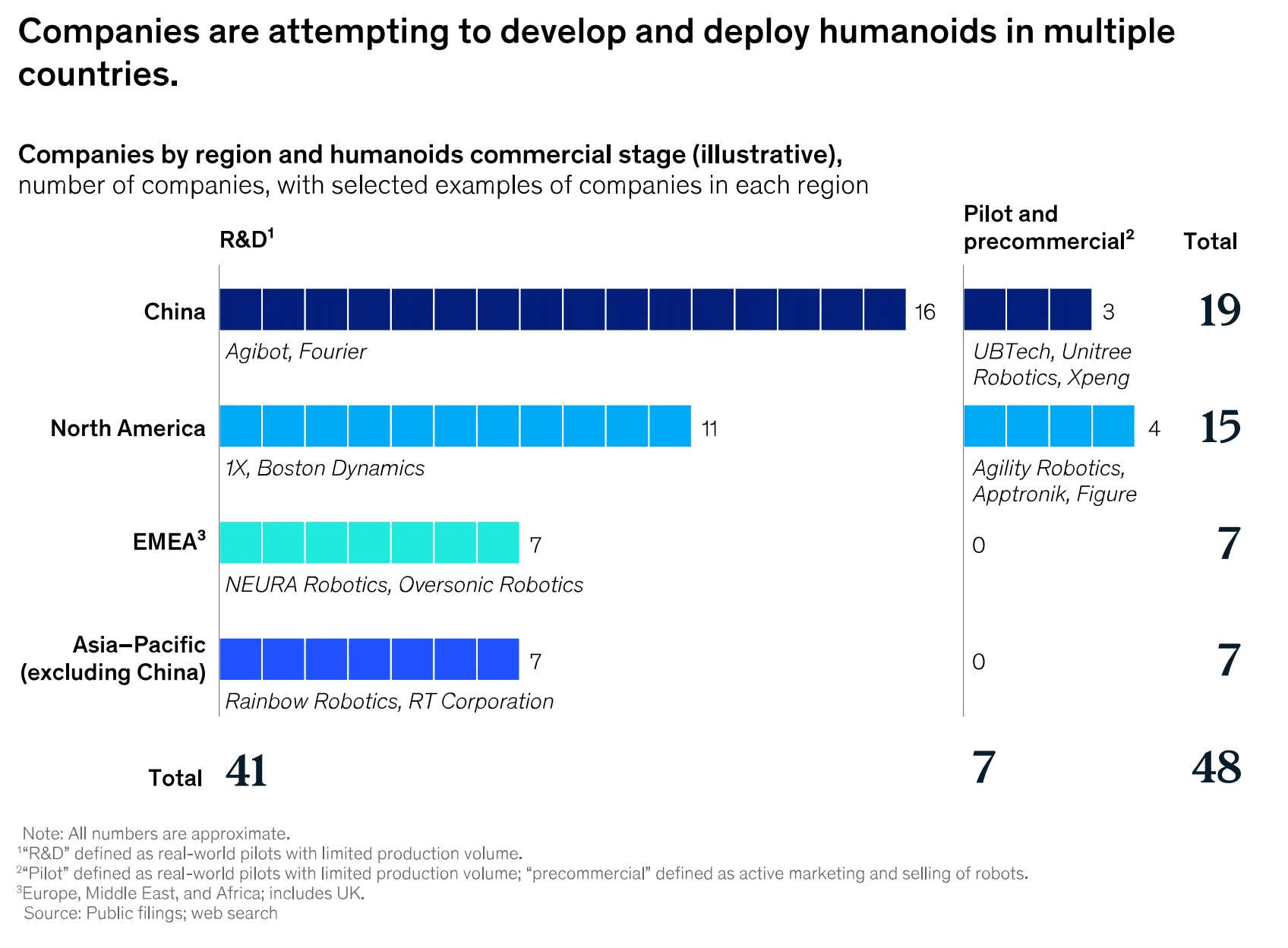

China produced over 10,000 humanoids in 2025 alone. That's 70% of all humanoids worldwide.

And in Europe? Just 6%. According to McKinsey, only 7 humanoid companies exist here. None have reached pilot phase yet.

7 companies, none of which are in the pilot phase (McKinsey)

The Old China Playbook

Beijing leaves nothing to chance.

Late 2023, China's Ministry of Industry declared humanoids a strategic priority. The goal: Mass production by 2025. They're treating robots like EVs 15 years ago.

The playbook is familiar: Subsidies for manufacturers and for users. Produce in China and you get your robot practically sponsored.

No country has more humanoid startups. Over 35 new models launched in 2024 alone.

In 2025, China invested $3.4 billion in robotics. 42% more than the US. 70% of the global supply chain already sits there.

If China continues this way, we know how it ends. Just like with EVs.

Build Robots or Buy Robots?

What if the biggest value driver isn't factory savings? What if the robot itself becomes the product?

Morgan Stanley projects: The humanoid robot market could reach $5 trillion by 2050. The entire global auto market today: $3 trillion.

This isn't a niche. An entirely new core business is emerging.

And that's pretty attractive for automakers.

We see two strategies:

Some build robots as new products. Tesla, Xiaomi, Hyundai, BYD. They're expanding their portfolio. Betting that the robot becomes the next car. Not just for their own factory. But for the market.

Others use robots as tools. BMW, Mercedes. They buy robots. From Figure. From Apptronik. The goal? Making car production cheaper and more efficient.

On one hand: Valid focus on core business.

On the other: The familiar risk. German companies become dependent on tech from China and the US.

So What About Germany?

There are promising players. NEURA Robotics builds humanoids. Schaeffler is making a strategic pivot. From cars to robots. At CES, they showcased drivetrain components for humanoid robots.

For German suppliers, this is an opportunity. The robotics market grows faster than automotive. Those who build components for cars today could build components for robots tomorrow.

McKinsey says: 40-60% of a humanoid's cost goes to drivetrain components. Supply them, and you earn on every robot sold.

Then there's KUKA. Germany's former world leader in industrial robots. In 2016, China's Midea bought the company. German know-how, built over decades. Then transferred to China. For many in Germany, it's the nightmare scenario all over again.

My Take

But here's what I think: There's still a chance. Especially for Europe.

If a robot costs the same in Germany as in China, why produce there?

For decades, production moved to Asia. The reason: Low labour costs.

If robots eliminate that cost advantage, other factors matter again. Proximity to customers. Shorter delivery times. Stable, resilient supply chains.

But I see two risks:

Many companies aren't ready. They're still fighting digitalization. Cloud migration. Data silos. AI pilots. These are the basics companies haven't mastered yet. Robots build on top of that. They are the next layer of digitalization. They need clean data and connected systems. If you can't handle that, robots won't help.

Germany could block its own path. Again. New technologies always follow the same pattern here. Scepticism. Over-regulation. Lost competitiveness. And this time there's more: It's only a matter of time before unions and worker representatives declare war on humanoids.

Few industrial locations need robots as urgently as Germany. High wages. Expensive energy. Missing skilled workers. And a manufacturing base under pressure. Robots are the missing puzzle piece. Germany should be going all-in.

But Germany is also the place most likely to resist.

But here's the thing: Industrial robots didn't destroy jobs in the end. They took over tasks nobody wanted anymore. And simultaneously created foundations for new industries and jobs.

The good news?

It's not too late. Germany is still in the race.

The question is: Will Germany act this time?

That's all for today.

What did you think of today's email? |

Feel free to reply to this email with your thoughts.

Until next week,

Philipp

PS: If you find value in this newsletter, please share it with someone who might benefit.

After 10 years at Mercedes-Benz, I quit in 2020. In 2024, tarted writing "Der Autopreneur". It became Germany's largest newsletter on automotive transformation. Now it’s also available in English.